Contents

- The first diesel engine fitted to a personal vehicle was in a VW Golf in 1976.

- General Motors didn’t put a diesel into a truck until 1982.

- Diesels were not turbocharged until the mid-1990s, when they were built for fuel economy.

- GM stuck with the Detroit Diesel engine for a few decades until the first Duramax was released in 2000.

- GM teamed up with Isuzu to develop the first Duramax 6.6-liter 90-degree turbocharged V-8.

Before the Duramax there was the Detroit Diesel Turbo Power

RPO Regular Production Option Codes (Engine Series)

There have been seven Duramax turbodiesel engines since their introduction at the turn of the new millennium:

- LB7 – 2001 to 2004, 300 horsepower, 520 pound-feet

- LLY – 2004 to 2005, 310 horsepower, 520 pound-feet

- LBZ – 2006 to 2007, 250 to 310 horsepower, 460 to 605 pound-feet

- LMM – 2007 to 2011, 300 to 365 horsepower, 520 to 660 pound-feet

- LGH – 2010 to 2017, 335 horsepower, 685 pound-feet

- LML – 2011 to 2016, 397 horsepower, 765 pound-feet

- L5P – 2017 to 2023, 445 to 470 horsepower, 910 to 975 pound-feet

- L5D – 2023, 350 horsepower, 700 pound-feet

Duramax Diesel Engines in Detail

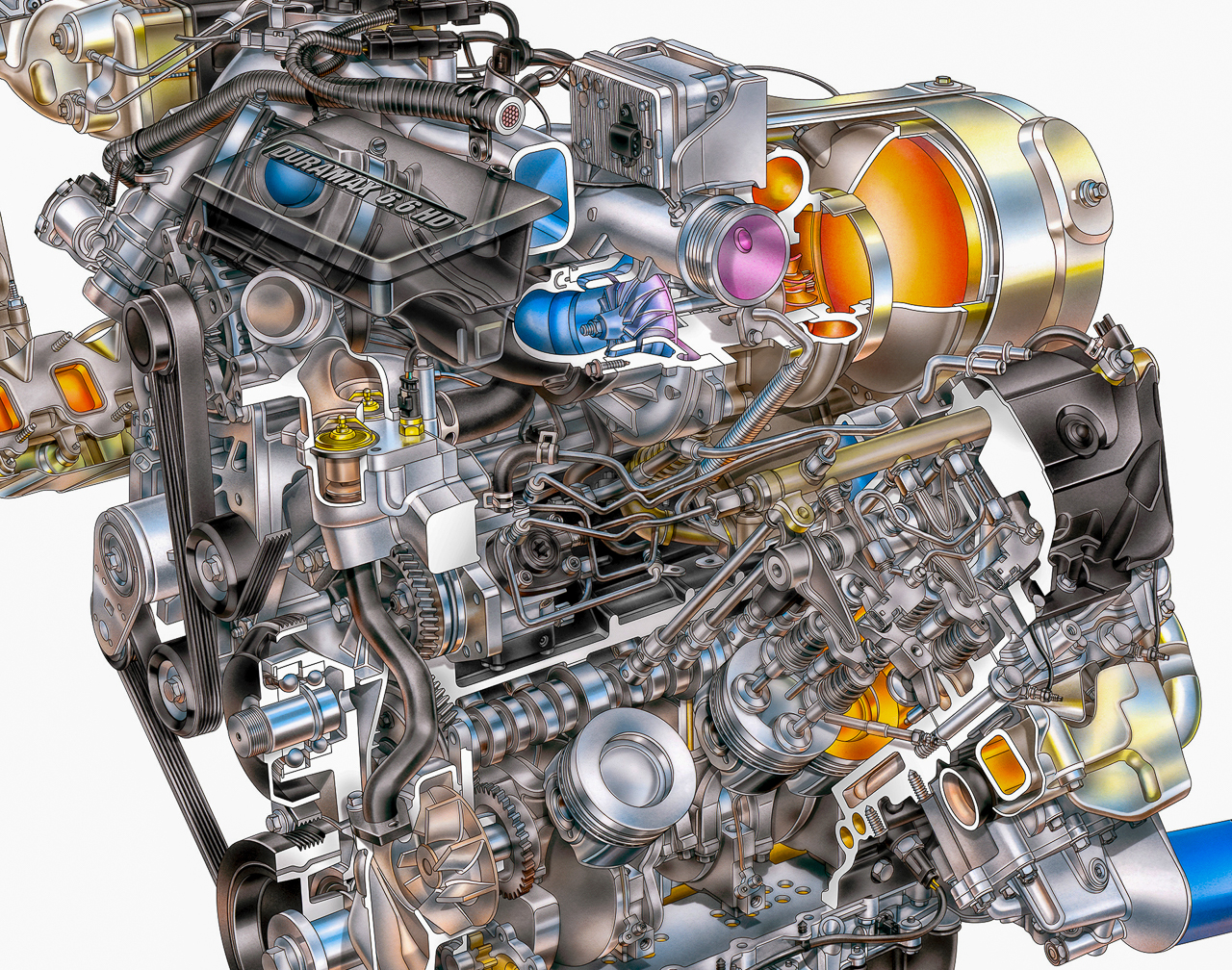

An inside look at the mighty Duramax L5P 6.6L turbodiesel V-8 (Source: GM)

Each of these models had their strengths and weaknesses. Let’s dive into the details.

LB7 (2001 – 2004)

This 32-valve engine with common rail direct injection uses a cast iron block with aluminum cylinder heads and 17.5:1 compression. The LB7 was plagued with issues such as weak head gaskets and fuel injectors that failed. When the injectors went bad, they would either leak into the oil or drip into the cylinder. Replacing the injectors is costly. The parts are not cheap, at around $2,000 for a set, plus $600 to $2,000 in labor.

A rebuilt and upgraded LB7 cylinder head

LLY (2004 -2005)

The first diesel equipped with emissions controls by GM, the LLY uses a Garrett turbo with an EGR system for emissions control. Common issues with this version are mainly with the cooling system and head gasket failures, as the head gaskets struggle to contain the higher cylinder pressure from the larger turbo.

The glow plugs in the LLY are controlled by a module that heats them to ignite diesel in cold engines, but the module has a bad habit of overheating them. A failed plug is one thing, but these plugs actually break apart, which is bad for pistons, valves, and everything inside an engine. The glow plug issues carry forward to the LBZ. The fix is a module reprogram and new glow plugs.

Discover: All About Exhaust Gas Recirculation (EGR) Valves

LBZ (2006 – 2007)

With a more robust block design and lower compression (16.8:1) than the LLY, the LBZ features thicker connecting rods, bigger piston pins, higher fuel pressure, and a better tune to accommodate more stringent EPA regulations while yielding more consistent performance for trucks and vans. These have long been considered the best Duramax diesel, and they’re the last GM diesel engines not to use diesel exhaust fluid (DEF), which is a big part of their popularity.

A Boostline forged I-beam connecting rod for Duramax

The LBZ suffers from water pump failures, which tend to occur around 80,000 to 100,000 miles. The impeller for the water pump on all Duramax engines (LBZ and earlier) is made of plastic, which breaks. Other issues are mainly caused by high-performance upgrades. The LBZ is capable of sustaining 600 horsepower, but beyond that, the pistons need to be upgraded to stronger forgings.

Shop now for Duramax partsLMM (2007- 2011)

The LMM brought forth the era of high-powered diesel engines in pickup trucks. These engines used variable geometry turbos, cooled exhaust gas recirculation (EGR) systems, new tuning, and low-ash oil. The cylinder heads were updated with better water passages to increase cooling capacity and sustain the much hotter temps due to the DEF regeneration cycles.

The Garrett turbo for Duramax LMM engines

There were two additional versions of the base LMM: the LGH and LML models. These are the first GM diesels to use DEF systems to clean the exhaust.

Get More: Facts About Diesel Exhaust Fluid

LGH (2010 – 2017)

Used primarily in vans and box trucks, the LGH uses a DEF system for emissions control. Inside, the LMM is pretty much the same as the LBZ, but with a new DEF system that was not very good. Fuel economy was reduced, and external component failures were the most common issues. You must upgrade the rods and pistons if you want more than 600 to 650 horsepower.

This Duramax-powered custom is not your average Chevy Express van.

LML (2011 – 2016)

This high-power version of the LMM still met the newest EPA standards. Fuel pressure was up to 29,000 psi, and the fuel system injected raw diesel into the exhaust to assist the DEF system in cleaning up particulate matter. The internal engine components were dialed in with the LMM: the rods and pistons were lighter and stronger, and the stock rotating assembly can support 700 horsepower.

Common issues for LML Duramax diesel shift from the engine itself to the DEF system. The typical weak point is the Bosch CP4.2 injector pump, which boosts the diesel fuel pressure to 30,000 psi. Without a secondary lift pump, the new pump had less flow and couldn’t support additional power demand much above stock levels. Dirty fuel is the biggest issue here, as it will kill the pump. These pumps die without warning, and you might get five minutes of symptoms before it craters, including poor performance, misfiring, and a check engine light.

Read: Reduced Engine Power and What You Can Do About It

L5P (2017 – 2023)

The L5P engine was the most potent Duramax engine until the Gen 2 L5P for 2024 models. Internally, the L5P has a more substantial block, a new cam design, better glow plugs, a larger oil cooler, and an upgraded EGR system.

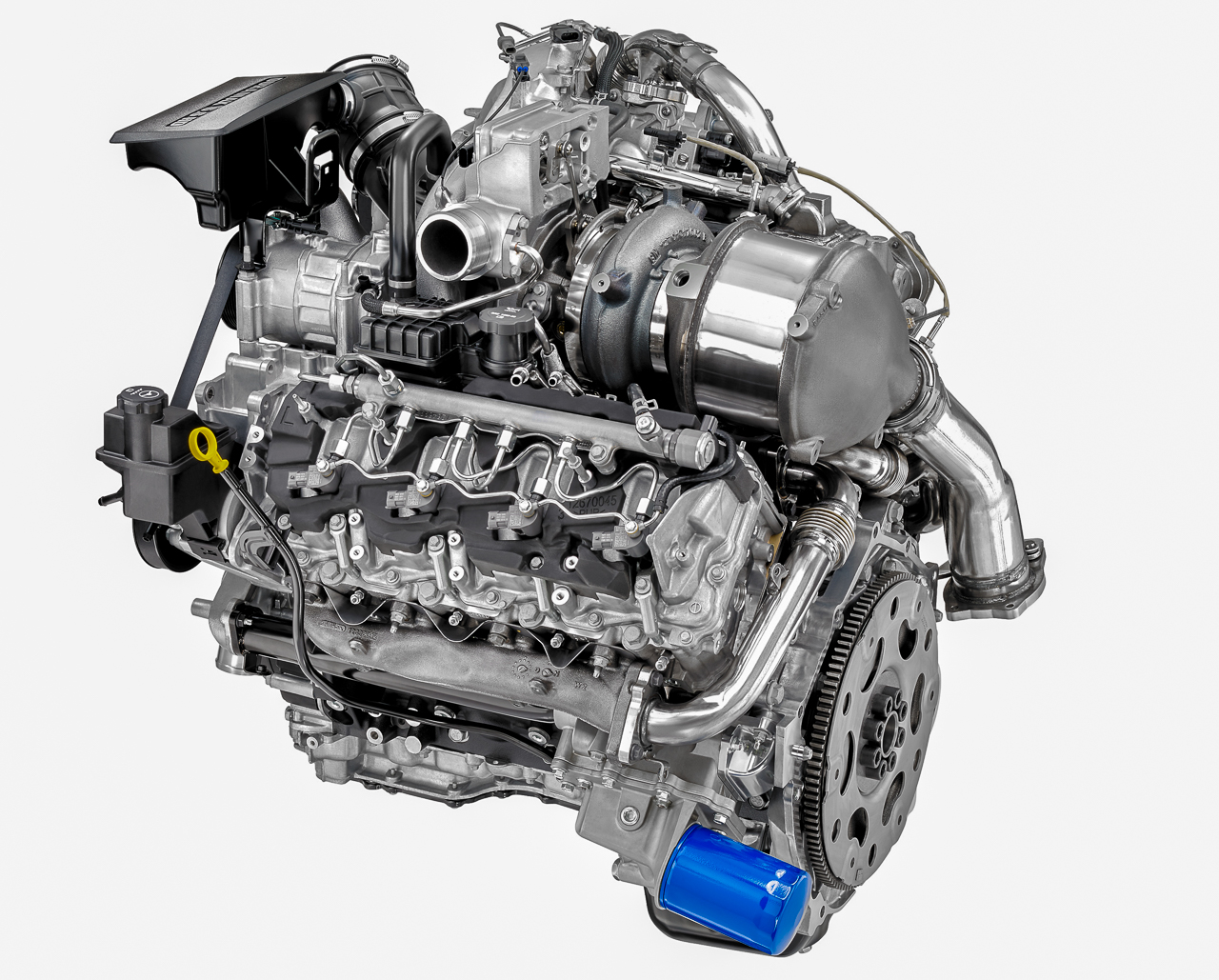

The L5P Duramax horsepower king was only recently dethroned. (Source: GM)

These DEF-controlled diesels are considered the most reliable of all the GM diesels. The fuel pump was swapped for a Denso HP4, which can support 800 horsepower, over the old Bosch CP4.2, which saves thousands of dollars in repairs. They do have some issues, though, as the DEF systems fail without regular maintenance, and the glow plugs wear out quickly even if you pay attention and always wait for the “wait to start” light to go out.

Another critical issue for the L5P is the injector plugs, which have a bad habit of melting when the injectors get hot. The MAP sensor in the intake is ridiculously simple, but it gets clogged up with carbon very quickly. This will set off all seemingly unrelated codes when the real culprit is a dirty MAP sensor.

They are still easily 500,000-mile-plus engines without major servicing if you maintain them. The more powerful Gen2 L5P comes in most 2024 GM 2500 and 3500 HD trucks.

One pickup driver’s misfortune could be your Duramax liftout swap

L5D (2023)

The L5D has reduced output for increased durability. Fitted to GM medium-duty trucks where the engine pulls heavy loads at slower speeds in commercial duty, the L5D makes sense for durability, maintenance downtime, and general economy.

Ready-to-swap L5P and Allison 10-speed transmission liftout.

Duramax engines are considered the most reliable V-8 diesels ever built. While there are a couple of issues here and there, such as the injectors in the LBZ and water pump failures for all of them, proper maintenance ensures these diesels will be ready to pull your house from its foundation if you ever need to. Easily upgraded and tuned, a Duramax is a good high-torque diesel. You can even get affordable aftermarket controllers, harnesses, and swap components for the L5P, making it one of the most swap-friendly V-8 diesels on the market.