Understanding sway bar links begins with the sway bar. The sway bar is also known as the stabilizer bar, anti-roll bar, or anti-sway bar.

The body of your car sometimes wants to lean, pulling away from the direction you are turning. Front and rear sway bars have the job of limiting body roll. They link the frame or subframe and suspension with a spring steel bar. That’s where the sway bar links come in.

Sway Bar Mounts and End Links

The rubber bushings on each end of a sway bar link alleviate vibration within the vehicle.

The steel sway bar is a torsional or twisting spring. It works differently than a coil spring. A pair of mounts secure the center of the bar to the frame or subframe. End links connect the bar to the suspension and the wheels, typically at the lower control arms. As your car corners, the twisting sway bar resists body roll. That twisting force keeps the inside wheel on the pavement.

In a straight line, the steel spring sway bar adds stability. It also smooths out the ride over uneven road surfaces.

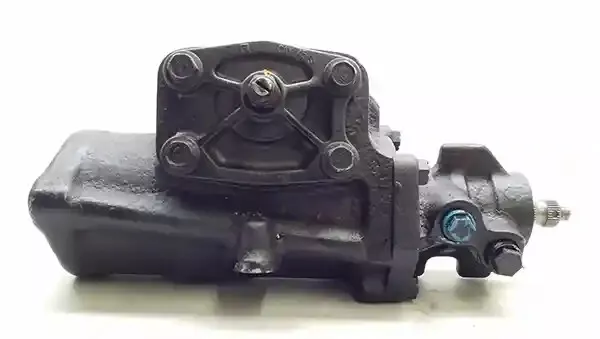

Mounts use a steel bracket around a rubber bushing. This basic layout both secures the sway bar and isolates the vehicle from vibration. The specific design can vary. Sway bar end links use a bolt and bushings, ball and socket, or a combination of the two to secure the ends of the bar to the suspension. The different designs allow for some travel as the wheels and tires roll down the road. Terminology and word usage vary, but sway bar links, stabilizer bar end links, and anti-roll links refer to the same part.

When to Replace Sway Bar Links

If a sway bar link’s bushings are significantly deformed, replace the swap bar links.

Road salt or driving on rough roads can accelerate wear, but there is no universal service life standard for sway bar end links. Finding out how long bushings and links last begins with a visual and mechanical inspection. And you do need to inspect the parts.

Most symptoms of bad sway bar end links can be caused by other problems. Blown shocks, spongy strut mounts, worn steering parts like tie rod ends and ball joints, worn-out wheel bearings, bad strut rod bushings, or bad alignment can all make the same sounds.

Fortunately, checking for sway bar link wear is easy. Park the vehicle with the wheels on level pavement or use a jack and jack stands to get both or all of the wheels off the ground. One wheel at a time won't work. The wheel on the ground compresses the sway bar and loads up the other side. Look for rusty, cracked, flattened, or deformed bushings and ball-and-socket end link seals. Grab the sway bar and check for excessive play or slop at the sway bar mounts and end links. The tiniest amount of play in a ball-and-socket end link can make a rattle down the road.

Symptoms of Bad Sway Bar Links

If your car feels loose in the corners, worn-out sway bar links may be the culprit.

Clunks, rattles, thumps and creaks

Rattling or clunking noise is the most obvious symptom of worn-out end links. Bad ball and socket or ball joint end links make a metal-to-metal rattle over the slightest bump in the road. Worn bolt and bushing end links also rattle while driving. They can also cause a creaking or groaning noise when turning the steering wheel while you’re parking. Worn sway bar mounts typically make a duller, hollow thumping sound over bumps, but they can rattle in severe cases.

Loose links and unstable handling

Pay attention to any loss of steering precision and stability that the sway bar usually provides. It can result in excessive body lean while cornering. You might notice wallowing during high-speed highway driving or in sudden maneuvers like lane changes. End link or bushing wear can be gradual. Over a long period, the loss of stability and increased body roll can be difficult to perceive. The sudden failure of a ball and socket end link can cause instantly recognizable steering instability. Other symptoms include vague steering response and uneven tire wear.

Is it okay to drive with broken sway bar links?

No. You may have already been driving down the road with a worn sway bar link. That could be the rattle you’ve been hearing. But if you hear something now, make repairs as soon as possible.

Fix your end links before they break. Sway bars snake up and around suspension and brake parts, engine-driven pulleys, CV axle drive shafts, and body structures. Sway bar mounts and links prevent the steel bar from thrashing around while you drive. You don't want to hear a spring steel sway bar hit a spinning crankshaft pulley.

What to Expect Replacing Sway Bar End Links and Bushings

If there’s no rust, it’s easy to remove and replace a sway bar link.

If your end links move or clunk around your hand, it’s time for some new parts. It’s the same story if your sway bar bushings look like they went through a Play-Doh Fun Factory.

Most end link setups are nuts-and-bolts simple. It makes removing and replacing sway bar links an easy and rewarding job. Of course, road salt can make the job a pain, but that’s true of any under-the-car repair. Road salt is the enemy of professional mechanics and DIY wrenches alike.

If you've ever changed the bushings on a skateboard truck, you can remove and replace a set of end links. Unlike removing and replacing bad tie-rod ends, ball joints, or control arm bushings, swapping in a new set of sway bar links does not disturb wheel alignment.

See our detailed article and video about how to replace sway bar end links - opens in new window or tab.. They include complete step-by-step instructions.

How much should you should on new sway bar links and bushings?

Conventional bushing and bolt sway bar links are the least expensive options available to you. Ball and socket or hybrid end links generally won't break the bank either. Upgraded performance sway bar setups or specialized off-road quick-release end links can add complexity and cost to the equation. Read our sway bar links buyer's guide - opens in new window or tab. for an in-depth look into the types of bushings and links available.

Share your feedback

This article is meant to provide general guidance only. Automotive maintenance, repair, upgrade, and installation may depend on vehicle-specifics such as make and model. Always consult your owner's manual, repair guide for specific information for your particular vehicle and consider a licensed auto-care professional's help as well, particularly for advance repairs.